Manufacturing companies can better meet eco-friendly production demands by taking several key steps. These include optimizing production processes, reducing energy consumption, improving waste management, and promoting a circular economy.

By implementing a waste reduction program, designing sustainable products, using recycled materials, and remanufacturing used parts, manufacturers can reduce environmental pollution, save time and money, and meet growing demand from eco-conscious consumers.

Reduce Waste

Manufacturers focusing on green production methods can lower their energy consumption, increase efficiency and help to protect natural resources. This can improve their competitive ability for government contracts and other opportunities.

Reducing waste is one of the most important ways to move toward the benefits of sustainable manufacturing. This can include the use of recycled materials in products and packaging, as well as implementing take-back programs for products. In addition, manufacturers can also reduce waste by designing new products that require fewer raw materials to manufacture and ship. One effective approach is to incorporate personalized mailer boxes by Arka crafted from recycled and eco-friendly materials into your packaging solutions. Furthermore, designing products with longevity in mind, promoting repairability, and implementing take-back programs for items at the end of their lifecycle can significantly contribute to a more sustainable and eco-conscious manufacturing process.

Finally, companies can reduce waste by implementing digital technological solutions such as predictive maintenance. This software can spot the earliest signs of equipment wear and tear, helping to prevent unplanned downtime and reduce overall energy use.

Many companies avoid sustainable production methods because they believe it will cost them more money upfront. However, the truth is that this is not necessarily true. By reducing waste, manufacturers can save themselves money in several ways, including cutting costs, improving efficiency, lowering environmental impact, enhancing brand reputation, increasing resilience and sustainability, and assisting with compliance.

In some cases, manufacturers can even get a return on their investment in sustainable production techniques. For example, if a company uses recycled plastic to produce its Bell chair, it can recycle it again into another product later.

Reduce Energy Consumption

The manufacturing process requires a great deal of energy to produce materials for product use. However, these processes can also release a lot of pollutants that negatively affect the environment. By using alternative energy sources and making other sustainable production choices, manufacturers can simultaneously reduce their environmental impact and save on operational costs.

For example, eco-conscious companies can use natural rather than synthetic materials when choosing raw materials for a new product. This reduces waste and prevents the creation of potentially harmful byproducts. Additionally, when sourcing energy for a facility, businesses can invest in renewable sources to help protect the environment. This can also future-proof the company against a potential energy shortage and improve its public image by showing customers that it cares about environmental issues.

Many steps in a transition to sustainability are simple and can significantly affect a company’s bottom line. By reducing energy consumption, improving recycling practices, engaging in time-saving initiatives, and promoting eco-conscious products, manufacturers can enhance their brand reputation, attract consumers, and boost employee loyalty. With global concern over climate change and dwindling natural resources, focusing on sustainability can improve productivity and help a business stay competitive in an increasingly environmentally conscious market. Moreover, implementing these strategies will make a business more profitable and create long-term value.

Reduce Pollution

Using eco-friendly materials in production reduces the amount of harmful chemicals that are released into the environment. It also reduces waste, conserves energy, and cuts costs by eliminating the need to recycle or dispose of materials after use. These practices show that the company cares about the planet and those who live here, and this can go a long way toward building trust with consumers over time.

Another way to reduce pollution is by switching to renewable energy sources. This will help decrease dependence on fossil fuels and lower carbon emissions in manufacturing. Additionally, it will future-proof the company against a potential phase-out of fossil fuels in the next century.

Other sustainable methods and practices include using recycled raw materials, reducing toxic chemicals in production, and implementing processes that eliminate airborne VOCs (volatile organic compounds) in manufacturing. Many of these practices are relatively simple to implement and can significantly impact manufacturing, decreasing energy consumption, waste, and pollution.

Increasingly, manufacturers are recognizing the need to be more environmentally conscious in their operations, especially given the disproportionate impact of industrial processes on the environment. This is driving a new paradigm for business that embraces the dual mission of profitability and sustainability. To meet this challenge, manufacturers must be able to analyze and monitor their environmental impact in near real-time. Converged industrial platforms integrating information technology (IT) and operational technology (OT) systems to enable real-time data analysis are critical to this effort.

Promote a Circular Economy

To fully transition to sustainable manufacturing, look closely at every area of its production process. This includes looking at raw materials, energy consumption, and waste management systems. Moreover, they need to begin promoting a circular economy. The EPA defines this as “the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.”

A circular economy requires manufacturers to design their products for disassembly and reusability. It also requires them to use recycled raw materials and implement closed-loop recycling processes. The goal is to create a system where products are reused as often as possible before they are disposed of safely and responsibly.

The benefits of a circular economy are numerous. It can help companies lower production and operational costs, promote innovation, and boost economic growth. It can also improve employee, community, and product safety. Lastly, it can help companies become more self-sufficient and sustainable by reducing reliance on a single source of raw materials.

Taking the steps to transition to sustainable manufacturing isn’t easy, but it’s well worth the effort. It is suitable for the environment and a great way to make your business more profitable and competitive in today’s global marketplace.

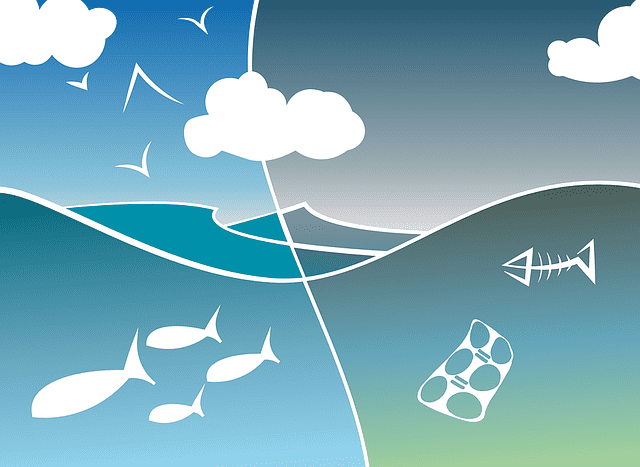

Featured Image by 政徳 吉田 from Pixabay