Across Oklahoma, daily work scenes often involve cracked oil drums near rigs, tractors idling in fields, and semis parked on slick I-40 shoulders. Drilling sites, ranches, manufacturing plants, and emergency calls all carry a higher risk of Catastrophic Injuries due to heavy machinery, remote locations, long shifts, and frequent exposure to hazardous materials.

For workers, supervisors, and families, prevention starts with clear steps: inspection logs on rigs, rollover bars on tractors, load-verification procedures for truckers, equipment audits in plants, and scheduled recovery time for first responders. Consistent safety lists and steady communication lower severe accidents and protect both lives and paychecks through small, practical changes.

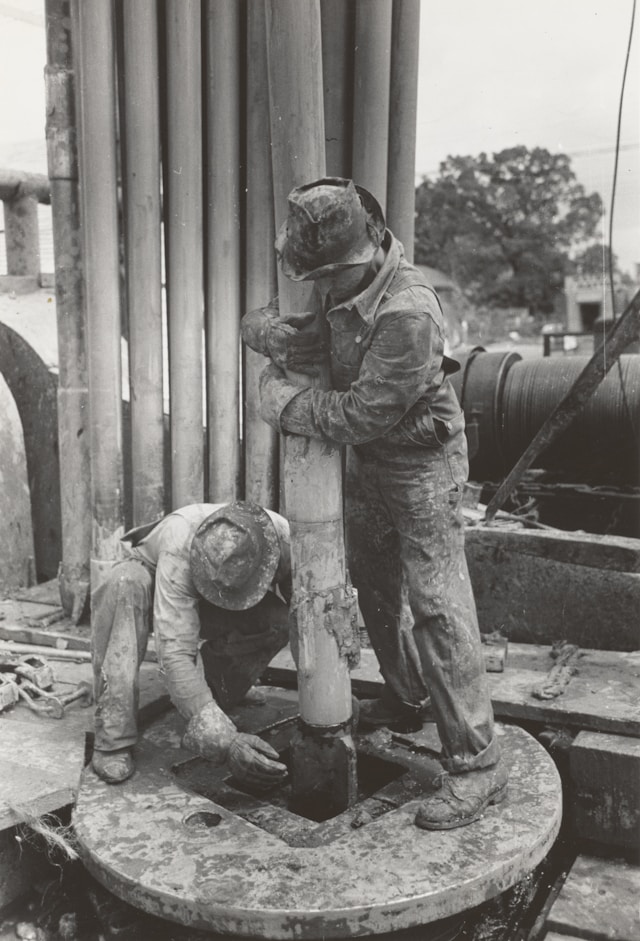

Oilfield Workers and Drillers

At Oklahoma drilling sites, explosions, crush injuries, and pressure-related accidents often come from outdated procedures or skipped maintenance. A personal injury lawyer in Oklahoma frequently handles cases caused by failed valves, unsecured rigging, or incomplete safety logs. Even small gaps in inspection records or missed lockout steps can result in permanent injuries to crew members and their families.

Crew chiefs should record visual checks of cables, valves, and drill heads before each shift and apply full lockout/tagout during mechanical work. Photo-verified maintenance logs protect both crew members and companies during investigations. Rotating experienced workers through safety oversight and updating shift-change checklists keeps accountability consistent on remote rigs.

Agricultural and Livestock Professionals

Farmers and ranch hands face a mix of heavy machinery and unpredictable animals, which increases the risk of Catastrophic Injuries, especially when work is done alone on remote fields. Long distances to clinics and uneven terrain make timely care difficult, and common incidents include rollovers, crushes, and animal kicks that produce severe trauma.

Retrofitting tractors and combines with rollover protection and automatic engine kill switches cuts the odds of Catastrophic Injuries, while ventilated storage for pesticides, fertilizers, and fuel away from livestock lowers exposure and fire risk. Two-person teams for animal transport or treatment reduce lone-worker hazards, and pre-mapped GPS-accessible routes to rural emergency services speed medical response, improving outcomes.

Truck Drivers and Freight Operators

Long hauls and regional routes across Oklahoma expose truck drivers to fatigue, shifting cargo, and sudden weather changes that can cause rollovers or jackknifes. Late-night hours and limited parking options increase exhaustion, while uneven loads often move during curves or gusts, putting both drivers and nearby motorists at serious risk of catastrophic crashes.

Digital checklists that confirm load securement, tire condition, and weight distribution before departure cut preventable accidents. Fatigue-monitoring systems linked to cab alerts help drivers rest before their attention drops. Route scheduling should prioritize rest compliance rather than tight deadlines, and seat or control adjustments ease strain for long-distance drivers, improving safety and limiting long-term injury.

Manufacturing and Plant Technicians

Oklahoma’s manufacturing plants expose technicians to moving machinery, heat, confined spaces, and chemical hazards that can cause severe injury. Older facilities are most vulnerable when new equipment arrives without proper training, forcing operators to handle controls they don’t fully understand. Routine maintenance can turn dangerous when safety barriers are bypassed or when worn parts go unnoticed.

Mechanical audits should follow production hours rather than calendar dates to capture equipment wear associated with heavy use. Add lift-assist tools to prevent spinal strain, require two-person lockout verification for all repairs or restarts, and post bilingual safety instructions so every worker can follow procedures accurately. These steps reduce incidents and downtime.

Emergency Responders and Correctional Officers

First responders and correctional officers face frequent physical strain, heat exposure, and high-stress incidents that cause both visible and lasting injuries. Short recovery times after major calls increase mistakes and delay healing. Scheduled cooldown periods between shifts help reduce muscle fatigue, lower error rates, and prevent long-term disability among Oklahoma emergency personnel.

Departments should upgrade protective gear to limit heat stress and improve impact resistance. Regular training on restraint safety and de-escalation techniques limits injuries during confrontations. Quarterly injury data reviews with outside safety specialists identify patterns early, allowing leaders to adjust staffing or procedures before problems become widespread.

Oklahoma’s most injury-prone jobs—oilfield crews, farmers, truckers, plant technicians, and first responders—face overlapping dangers: heavy machinery, long shifts, heat, and limited recovery time. Stronger safety routines and reliable recordkeeping turn daily risks into preventable incidents. Regular equipment inspections, rest-based schedules, two-person procedures, and updated gear sharply cut catastrophic injuries and financial strain. Employers who document hazards and fix issues early protect crews and avoid costly downtime. Practical safety steps—consistent checklists, verified maintenance, and clear communication—build steady habits that keep Oklahoma’s workforce productive, families secure, and industries running safely even under demanding and unpredictable conditions.