Print Techniques: An Overview

The print industry is experiencing a transformation unlike any in its long history. Often referred to as The Print Revolution, this shift reflects how modern businesses, creatives, and consumers require compelling visual communication—and the tools for fulfilling these needs have never been more powerful or diverse. At the center of this evolution are offset and digital printing, each with its own strengths and ideal use cases. For organizations aiming to produce memorable marketing materials, packaging, or publications, understanding contemporary print techniques is essential. Those seeking expert printing solutions, such as offset printing Scranton, can leverage these combined techniques to maximize quality, efficiency, and cost-effectiveness.

Offset printing continues to be recognized for its impeccable quality and consistency, particularly for high-volume projects. Meanwhile, digital printing has brought remarkable agility and personalization to the table, allowing for swift turnaround and the ability to tailor prints to individual recipients. Integrating the best aspects of both worlds through hybrid techniques is quickly becoming the new standard, propelling the print industry into an era of unmatched flexibility and performance.

Offset vs. Digital Printing: Key Differences

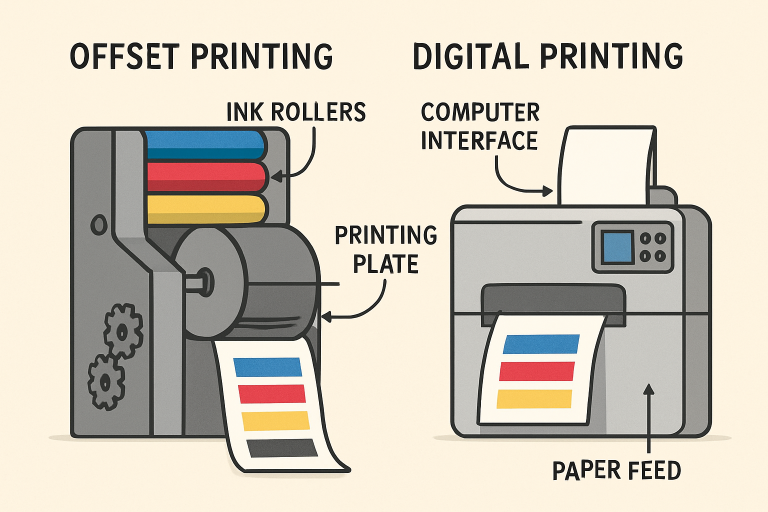

Offset and digital printing differ in terms of the machinery used. Offset uses a plate-based method, transferring ink onto paper through rollers, delivering vibrant, color-consistent results. It’s ideal for large print runs and becomes more economical as quantity increases. Digital printing uses direct-to-substrate technology, allowing short-run jobs, variable data personalization, and shorter setup times. Offset’s setup time and cost are justified for large runs, while digital’s flexibility and speed make it ideal for targeted campaigns and rapid prototyping. The key advantage is knowing when to use each method or combine them for strategic impact.

The Rise of Hybrid Printing

Hybrid printing is a new approach that combines the benefits of offset and digital printing. Often considered part of The Print Revolution, it allows printers to use offset’s volume efficiency and visual richness, while overlaying variable data with a digital press. This results in a cost-effective workflow that meets quality standards while enabling customized communication, a crucial aspect in data-driven marketing. Hybrid printing can be used for mass mailers with personalized messages or packaging with unique QR codes or serial numbers.

Sustainability and Printing

Sustainability is a priority both for consumers and for the print industry itself. Modern printing processes have made great strides, such as employing vegetable-based inks and recycled materials. Digital printing supports eco-friendly practices by minimizing setup waste and enabling precise print runs, reducing excess. Offset presses have advanced as well, featuring improved energy efficiency and streamlined chemistry for reduced environmental impact. According to Two Sides, these changes help print providers significantly cut their carbon footprint while maintaining high standards.

How to Choose the Right Printing Method

Selecting the right print strategy depends on several critical factors:

- Run Length: Offset shines for larger jobs, while digital is ideal for smaller, quicker projects.

- Personalization: If variable data is needed, digital or hybrid printing is optimal.

- Turnaround Time: Digital and hybrid approaches can often deliver faster turnaround.

- Budget: Balancing quality and cost, hybrid printing frequently yields the best return for complex, multifaceted campaigns.

By aligning the print method with project goals, businesses can ensure their message is delivered effectively and memorably.

Technological Advancements in Modern Printing

Rapid advancements in technology have further blurred the lines between offset and digital printing. Next-generation digital presses now nearly match offset for image quality and color fidelity, while workflow automation and artificial intelligence-powered quality control minimize error and reduce waste. Innovations in finishing—such as inline varnishing, embossing, and die-cutting—are now easily integrated into both digital and hybrid production lines. As covered by PrintWeek, the industry’s move toward smarter presses and streamlined digital workflows means faster job completion, less setup time, and highly customized outputs.

What the Future Holds for Print

Looking ahead, print is set to grow even more dynamic and sustainable. As part of The Print Revolution, hybrid printing will enable deeper customer engagement, while emerging technologies—like cloud-connected presses and augmented reality—will further blur the boundary between print and digital experiences. The focus on green practices will also continue, with investment in carbon-neutral and closed-loop processes. Businesses of all sizes can look forward to leveraging these evolving capabilities to elevate communications and boost campaigns, ensuring that print remains a vital part of the media landscape.